Welcome toWhat Is It? Wednesdays! Every other Wednesday, well explore a different ingredient or product in depth.Well be covering the benefits, uses, and common misconceptions about each.If you have any requests, leave them in the comments and well work them into the schedule.

Here at Bob's Red Mill, we are dedicated to the time-honored tradition of stone milling to provide you with the purest form of grains. Ever wondered what a stone mill is or how it works? Well, now you don't have to!

What is a stone mill?

What is a stone mill? A stone mill, also known as a grist mill, grinds a variety of grains using buhr stones instead of steel rollers.Because the millstones grind at a slow speed and cool temperature, the inherent nutrients and flavor of our grains are preserved, a production "secret" that allows us to seal in the freshness and bring you wholesome, quality foods, just as nature intended.

Where do our stones come from?

Where do our stones come from?Our operating millstones are hand quarried in La Ferte-sous-Jouarre, France. The stone has the advantage of occurring in a form with a myriad of very small holes in a flint-hard setting. The biting, or "lively" quality for grinding grain is owed to the flinty nature of the stone. Its very hardness means that a pair of stones will last a lifetime.

How does stone milling work?

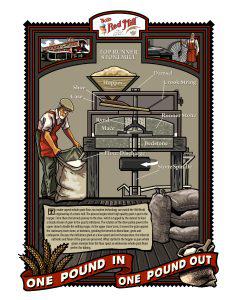

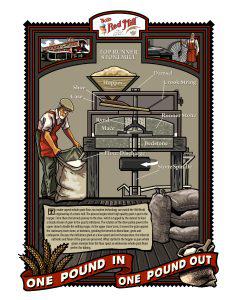

How does stone milling work? The grain starts out in a hopper, which holds the grain. Then the damsel shakes the grains so they can travel down through the shoe and into the eye of the upper stone. This is where the magic happens to provide us with whole grain goodness. Again, the millstones grind at a slow speed and cool temperature, and thats what helps preserve the nutrients and flavor of the grain. The size of the grain is determined by the distance between the two stones. Check out this fun

interactive graphic to see how this process works.

When did Bobs Red Mill start milling flour?

When did Bobs Red Mill start milling flour?

Bob's journey began in the mid '60s when he came across a book called

John Goffe's Mill that inspired him to search for his own stone mill. With a little time and persistence, Bob and his wife, Charlee, eventually found several sets of millstones in Fayetteville, NC, where they purchased them, had them shipped and began their first mill in Redding, California. In 1978 the couple left the mill and retired to Oregon City, but fate stepped in one afternoon when Bob came across an old mill that was for sale. A few months later, Bobs Milwaukie-based mill was producing stone ground flours and cereals for local customers . . . and those millstones are still turning!

Why use a stone mill for grinding?

Why use a stone mill for grinding?To make superb whole grain flour, we stick with this time-honored practice of stone milling so we keep the nutrients intact. No modern technology can match the Old World engineering of a stone mill. Our beautiful, century-old buhr millstones are much like the ones used during early Roman times. Unlike high-speed steel rollers, our quartz millstones ensure the most nutritious parts of the whole grain remain, so we can pack wholesome goodness right into your bag.Our grains remain whole grains because we dont remove the bran or germ, which you lose in processed grains. Want to hear Bob talk about our millstones? Check out this

video for more details from Bob himself!

If you ever come to Milwaukie, OR, come tour our facility! We would love to show you around our home.

What is a stone mill? A stone mill, also known as a grist mill, grinds a variety of grains using buhr stones instead of steel rollers.Because the millstones grind at a slow speed and cool temperature, the inherent nutrients and flavor of our grains are preserved, a production "secret" that allows us to seal in the freshness and bring you wholesome, quality foods, just as nature intended.

What is a stone mill? A stone mill, also known as a grist mill, grinds a variety of grains using buhr stones instead of steel rollers.Because the millstones grind at a slow speed and cool temperature, the inherent nutrients and flavor of our grains are preserved, a production "secret" that allows us to seal in the freshness and bring you wholesome, quality foods, just as nature intended.

Where do our stones come from?Our operating millstones are hand quarried in La Ferte-sous-Jouarre, France. The stone has the advantage of occurring in a form with a myriad of very small holes in a flint-hard setting. The biting, or "lively" quality for grinding grain is owed to the flinty nature of the stone. Its very hardness means that a pair of stones will last a lifetime.

Where do our stones come from?Our operating millstones are hand quarried in La Ferte-sous-Jouarre, France. The stone has the advantage of occurring in a form with a myriad of very small holes in a flint-hard setting. The biting, or "lively" quality for grinding grain is owed to the flinty nature of the stone. Its very hardness means that a pair of stones will last a lifetime.

How does stone milling work? The grain starts out in a hopper, which holds the grain. Then the damsel shakes the grains so they can travel down through the shoe and into the eye of the upper stone. This is where the magic happens to provide us with whole grain goodness. Again, the millstones grind at a slow speed and cool temperature, and thats what helps preserve the nutrients and flavor of the grain. The size of the grain is determined by the distance between the two stones. Check out this fun interactive graphic to see how this process works.

How does stone milling work? The grain starts out in a hopper, which holds the grain. Then the damsel shakes the grains so they can travel down through the shoe and into the eye of the upper stone. This is where the magic happens to provide us with whole grain goodness. Again, the millstones grind at a slow speed and cool temperature, and thats what helps preserve the nutrients and flavor of the grain. The size of the grain is determined by the distance between the two stones. Check out this fun interactive graphic to see how this process works.

When did Bobs Red Mill start milling flour?

Bob's journey began in the mid '60s when he came across a book called John Goffe's Mill that inspired him to search for his own stone mill. With a little time and persistence, Bob and his wife, Charlee, eventually found several sets of millstones in Fayetteville, NC, where they purchased them, had them shipped and began their first mill in Redding, California. In 1978 the couple left the mill and retired to Oregon City, but fate stepped in one afternoon when Bob came across an old mill that was for sale. A few months later, Bobs Milwaukie-based mill was producing stone ground flours and cereals for local customers . . . and those millstones are still turning!

When did Bobs Red Mill start milling flour?

Bob's journey began in the mid '60s when he came across a book called John Goffe's Mill that inspired him to search for his own stone mill. With a little time and persistence, Bob and his wife, Charlee, eventually found several sets of millstones in Fayetteville, NC, where they purchased them, had them shipped and began their first mill in Redding, California. In 1978 the couple left the mill and retired to Oregon City, but fate stepped in one afternoon when Bob came across an old mill that was for sale. A few months later, Bobs Milwaukie-based mill was producing stone ground flours and cereals for local customers . . . and those millstones are still turning!

Why use a stone mill for grinding?To make superb whole grain flour, we stick with this time-honored practice of stone milling so we keep the nutrients intact. No modern technology can match the Old World engineering of a stone mill. Our beautiful, century-old buhr millstones are much like the ones used during early Roman times. Unlike high-speed steel rollers, our quartz millstones ensure the most nutritious parts of the whole grain remain, so we can pack wholesome goodness right into your bag.Our grains remain whole grains because we dont remove the bran or germ, which you lose in processed grains. Want to hear Bob talk about our millstones? Check out this video for more details from Bob himself!

If you ever come to Milwaukie, OR, come tour our facility! We would love to show you around our home.

Why use a stone mill for grinding?To make superb whole grain flour, we stick with this time-honored practice of stone milling so we keep the nutrients intact. No modern technology can match the Old World engineering of a stone mill. Our beautiful, century-old buhr millstones are much like the ones used during early Roman times. Unlike high-speed steel rollers, our quartz millstones ensure the most nutritious parts of the whole grain remain, so we can pack wholesome goodness right into your bag.Our grains remain whole grains because we dont remove the bran or germ, which you lose in processed grains. Want to hear Bob talk about our millstones? Check out this video for more details from Bob himself!

If you ever come to Milwaukie, OR, come tour our facility! We would love to show you around our home.